Company

Did you think all textile products are made in Asia? You thought wrong. Since 1866 Moll has been producing exclusively in Germany. At first, the family enterprise was founded as a traditional braiding shop and weaving mill close to Wuppertal. More than 50 years ago a branch was opened in Altshausen near Ravensburg. Today, this is where you can find our main location, a team of highly motivated employees, a modern machine park for the production and extraordinary products made in Germany.

Our experience

For more than 150 years, we have been intensively involved with the manufacturing of elastic ribbons and lace and may call ourselves specialists in this area. During this time, our developers generated various products in close cooperation with our customers; these fulfill diverse requirements. In the individual product areas “Fashion ribbons” and “Technical ribbons” we want to show you some examples of what we have already realized for our satisfied customers.

Our values

First of all, as our customer you are the focus of our efforts. As required, you receive fashion or technical articles with consistently high quality, which meet your requirements. It is our goal to grow along with our customers and to advance cooperative developments. This requires high flexibility, reliability, competence, innovative strength and a strong adherence to schedules from us. Our modern technology and an experienced team with sound training support this promise of services.

Moll – a tour

This gives you the chance to get a little insight into our production facilities. We would like to invite you to visit us directly in our main plant and get our own impression. All of our facilities are established to manufacture optimal products.

In Altshausen we have a warping facility, an extensive machine park for ribbon production and also a dye factory with processing.

The preparation for the weaving or crocheting of ribbons, lace and technical textiles takes place here. In the warping facility we process yarns of quality European manufacturers into warp beams. Our own warp preparation facility gives us the opportunity to implement your requirements in regard to customer specific patterns or a shortened delivery time of serial products quickly.

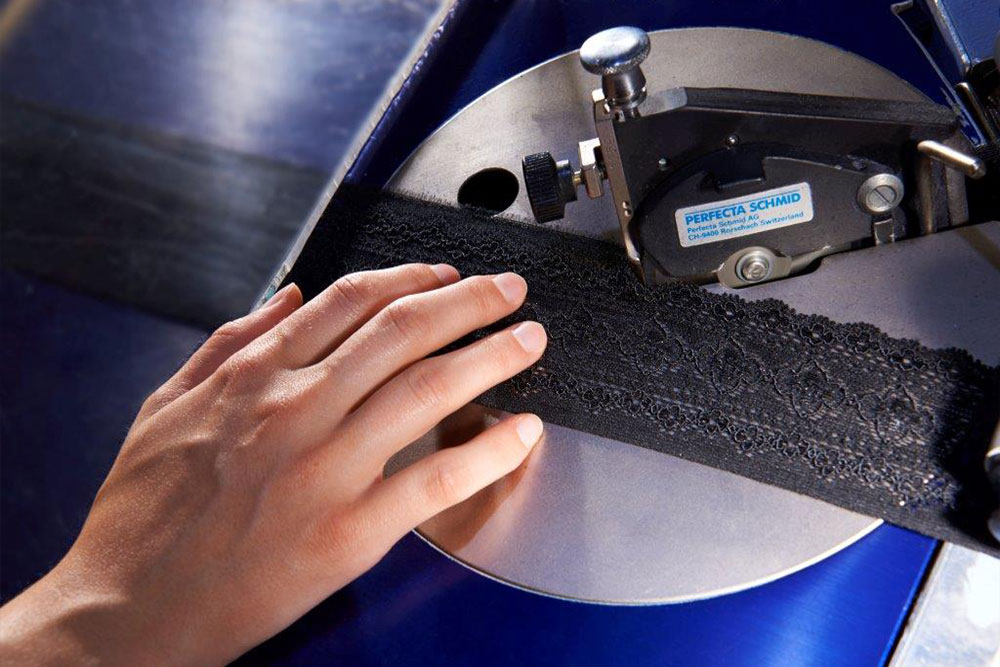

In Altshausen our ribbons are manufactured on different ribbon weaving machines and crocheting machines of the leading manufacturers Comez, Jakob Müller and Mageba.

The most updated production technologies of our facilities can, depending on binding and material, produce ribbons with different elasticities and ribbon widths of a few millimeters up to a width of 600 millimeters.

Our dyeing and finishing department includes the areas processing, finishing and dyeing. This department gives our ribbons additional features according to your profile of requirements. For example, ribbons can be heat-set to reduce the shrinkage values for later use. The topic color can also lend an individual character to a product. In our own dyeing facility we react quickly and with flexibility to your requirements and provide you with small sample amounts in a timely manner.

After the production of the raw materials and additional processing steps, the finished products are packaged according to customer requirements and shipped. In addition to presentation in rolls, the goods can also be provided lose in boxes for further processing.

After the goods have been carefully packaged, they are either shipped directly to the customer or remain in our storage until called up by you.

We perform ongoing production monitoring as well as random sample controls of the final products, so that you can rely on our products.

The majority of our products are produced with yarns of European origin.

You can also see our high demands to quality in our certifications. We have already been successfully certified according to ISO 9001. Furthermore, we are certified under test number 93.0.4072 under OEKO - TEX® Class II for our entire range of products. A very large portion of our products is already supplied according to the thresholds of Class I.